- Applications

• Pharmaceutics

• Food and beverage

• Oil industry

• Semiconductor

• Chemical industry

• Prefiltration for RO

• Paints & Coatings

• Cosmetics

• Photographic and plating solutions

• Air and gas filtration

Material of Construction

Filter media: PP-Polypropylene, GF-Glass fiber

Support layer: PP

Core / Cage / End adaptor: PP

Seal Material : Silicone, EPDM, Buna, Viton, Teflon

Recommended Operating Conditions

Max. Differential Pressure:

Forward- 75psi (5.1bar) at 25°C

Forward- 25psi (1.7bar) at 80°C

Reverse- 30psi (2.0bar) at 25°C

Filters change recommended at 1.5-2.0bar

Max. Operating Temperature: 80°C

Sterilization: 5times, 20 Minutes cycles at 121°C

Cartridge Dimensions

Filtration Area: 0.5m2 each 10" length

Outer Diameter: 69mm

Nominal Length: 5", 10", 20", 30", 40"

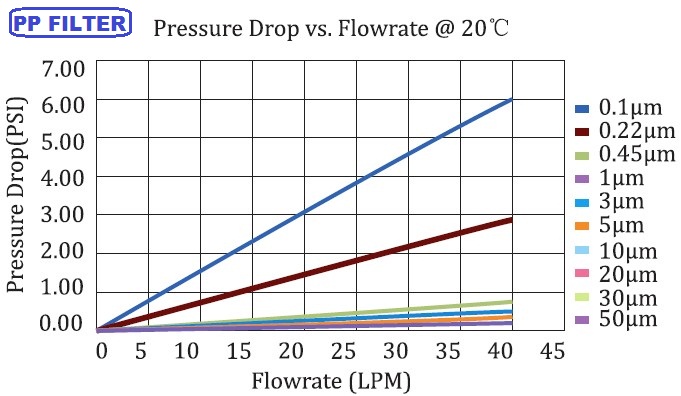

Micron rating: PP - nominal 0.1, 0.2, 0.45, 0.65, 1, 3, 5....μm

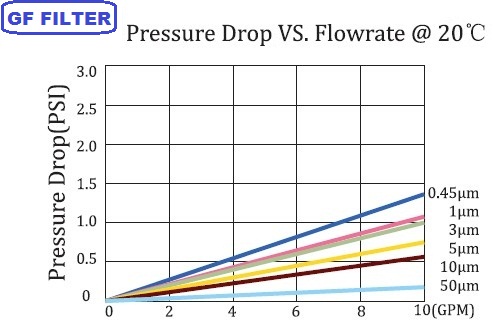

GF - absolute 0.45, 0.65, 1, 3, 5....μm ß5000(99.98% efficiency)

Ordering Guide

| Model WF | Micron Rating | End Adaptor | Seal | Length |

|

WF- |

010:0.1μm 020:0.2μm 045:4.5μm 100:1μm 300:3μm ...... H10:10μm ...... |

CODE O - DOE Double Open 7 - 226/Fin 8 - 222/Fin 3 - 222/Flat Closed 2 - 226/Flat Closed F - 215/Flat Closed S - O-Ring Insert/Flat Closed |

E - EPDM N - Buna S - Silicon V - Viton T - Telfon |

10:10" 20:20" 30:30" 40:40" |